Design and installation of internal floating roof oil tanks

Categories:

Hong Kong Qingshan Power Plant 7000m undertaken by our company ³ Wave pattern painting on the outer wall of process water tank is completed! Recently, our company undertook 7000 m of Hong Kong Qingshan Power Plant ³ The external wall of process water tank is painted with wavy pattern. The completion of this work also indicates that Hong Kong Qingshan Power Plant is 7000m ³ The process water tank construction and installation project has been formally completed and will be put into formal production.

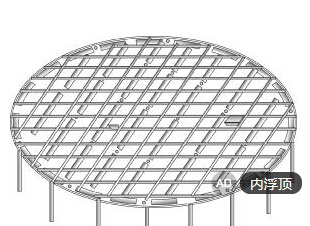

The internal floating roof oil tank is commonly referred to as an internal floating roof storage tank, floating roof oil tank, internal floating plate storage tank, internal floating plate oil tank, etc. It specifically refers to an environmentally friendly and economical storage tank with a series of materials such as aluminum and stainless steel installed inside the storage tank and oil tank to prevent liquid volatilization. It belongs to a volatile liquid storage tank with a floating roof installed under the arch of the storage tank, which is a combination of the arch roof and internal floating roof structure. The external arch of the storage tank is combined with the floating roof inside the tank, and it has been widely used in gasoline, aviation kerosene, and highly volatile chemical liquids.

Details

Code for design and installation of inner floating roof oil tank

1、 Executive standard for inner floating roof oil tank:

1. Domestic design standard: GB50341-2003 Code for Design of Vertical Cylindrical Steel Welded Oil Tanks

2. Domestic construction standard: GB50128-2005 Code for Construction and Acceptance of Vertical Cylindrical Steel Welded Oil Tanks

3. Foreign design standard: API650-2007 Standard for Steel Welded Petroleum Tanks

2、 Features of inner floating roof oil tank:

Internal floating roof tanks are generally called internal floating roof tanks, floating roof tanks, internal floating pan tanks, internal floating pan tanks, etc. Specifically, it refers to an environment-friendly and economical tank with aluminum, stainless steel and other series of internal floating roofs installed inside the tank and oil tank to prevent liquid volatilization. It is a volatile liquid tank with a dome roof tank and an internal floating roof structure. The external dome roof of the tank is combined with the internal floating roof of the tank, At present, it has been widely used in gasoline, aviation kerosene and volatile chemical liquids.

3、 Features of inner floating roof structure:

The inner floating roof or inner floating plate refers to the floating roof floating on the oil tank surface, which rises and falls with the oil and liquid. It is recognized that covering the liquid surface with this kind of inner floating roof is the most ideal economic and practical method to reduce the oil evaporation loss.

4、 Advantages of inner floating roof oil tank:

1. It has obvious environmental and economic benefits: in a specific climate environment, according to historical data, the economic value of reducing oil and gas volatilization within 3-6 months of adopting the inner floating roof is equivalent to the installation and procurement cost of the inner floating roof, that is, the cost of the inner floating roof can be recovered within half a year. It can be suitable for butt joint tanks and lap joint tanks of various specifications. It does not pollute oil products or chemicals, can reduce the volatile loss of media, and prevent air pollution. It is an ideal internal floating roof floating plate with low cost, short construction period, corrosion resistance, no volume occupation, and long service life.

2. It has the characteristics of high safety: the inner floating plate floats on the liquid surface, so that there is no evaporation space for the liquid phase, and evaporation loss can be reduced by 85%~90%; At the same time, the floating plate blocks the air and liquid storage, reducing air pollution and fire risk.

3. It has the advantage of long economic life: because there is no gas space on the liquid surface in the inner floating roof tank, it reduces the vibration generated during the transmission of liquid inside and outside the tank, prevents the impact of the stored liquid on the inner wall of the tank or the increase of the internal pressure, reduces the corrosion of the tank top and wall, and extends the service life of the tank.

5、 Applicable scope of inner floating roof oil tank:

1. Working pressure: atmospheric tank;

2. Working temperature: - 30 ℃~ 150 ℃;

3. Liquid medium: various oil products, including naphtha, gasoline, diesel, kerosene, crude oil, fuel oil, heavy oil, benzene, xylene, methanol and ethanol;

4. Tank volume: generally, it is not more than 10000m3 in current design.

Code for design and installation of large vertical oil tanks in China

1、 Executive standard:

1. Domestic design standard: GB50341-2003 Code for Design of Vertical Cylindrical Steel Welded Oil Tanks

2. Domestic construction standard: Code for Construction and Acceptance of Vertical Cylindrical Steel Welded Oil Tanks (GB 50128-2005)

2、 Design specification:

1. The codes used for the design of large oil tanks are mainly API 650, JIS B8501, British Industrial Standard BS2654 and Chinese National Standard GB50341 from a worldwide perspective. The formulas used in each code are derived from the formula for calculating the circumferential stress in the membrane theory. Combined with the stress characteristics of oil tanks, the allowable stress, weld joint coefficient and additional wall thickness become a complete wall thickness calculation formula, Each specification determines its own allowable stress and weld coefficient according to the performance characteristics of materials and construction technology level of its own country. Therefore, oil tanks of the same volume are calculated according to different specifications, and the calculation results of tank wall thickness sometimes vary greatly.

2. According to the performance characteristics of domestic materials and the allowable stress and weld joint coefficient specified by the overall level of domestic construction enterprises, the Chinese national standard GB50341-2003 is more in line with the national conditions. This code is basically adopted in the design of oil tanks in our country.

3、 Construction specifications:

1. Construction method: the construction of ordinary vertical storage tank basically adopts the chain inversion method: construction preparation → material inspection → blanking → processing → inspection → welding of tank bottom middle plate → bow edge plate of tank bottom → center column Erection of umbrella frame → assembly and welding of top ring → assembly and welding of wrapped angle steel → assembly of temporary vault support → guide chain lifting device → assembly and welding of vault → assembly and welding of lower ring → jacking of top ring wall plate → circumferential seam welding → assembly and welding of each circumferential seam → assembly and welding of bottom ring bottom plate corner seam → bottom plate edge plate → inspection → accessory installation → vacuum test → overall test → settlement observation → handover.

2. Tank body prefabrication: three arc templates: one template for checking the curvature of the vault, with chord length not less than 2m; Check one inner arc sample plate with chord length not less than 1m for deformation of vertical weld corner; Check one outer arc sample plate for vertical weld deformation, and its chord length shall not be less than 1m.

3. Tank body assembly: according to the tank installation sequence, the lower surface of the bottom plate shall be protected against corrosion before installation. Before laying the base plate, the vertical and horizontal cross center lines shall be drawn on the surface on the basis of qualified acceptance. When the center line deviation marked by civil engineering is large (but within the allowable range), it shall be adjusted to the minimum.

4. Tank welding and weld inspection: the welding process assessment of butt joints, T-shaped fillet welds and tubesheet shall be carried out according to JB4708-92 Welding Process Assessment of Steel Pressure Vessels, and the on-site welding process instructions shall be prepared. The radiographic inspection of tank welds shall be carried out according to GB3323-87 Radiography and Quality Grading of Butt Joints of Fusion Welding of Steel.

4、 Test method:

1. Tank body test: vacuum leak test for the bottom plate. The vacuum method shall be used to test the leak of all the bottom plate welds. The vacuum degree shall not be less than 53Kpa, and the penetrant flaw detection method shall be used for reinspection.

2. Water filling test of tank body: floating plate lifting test, foundation settlement observation. Then, temporarily close all the openings on the upper part, open the transparent holes on the tank top, and fill the tank with water. The test water shall be fresh water, the water temperature shall not be lower than 5 ℃, and the pressure shall be maintained for 48 hours.

3. Tightness test, strength test and stability test of the tank wall and top: when filling the tank with water, when the water level is higher than 1m, close the transparent hole and foam vent on the tank top, continue to fill the tank with water, and set a temporary pressure gauge on the tank top to observe the pressure reading. The pressure stabilization test shall be carried out after the water filling test. When the water filling reaches the maximum operating liquid level, all openings shall be closed, and the drainage shall be carried out slowly. The negative pressure in the tank shall be generated, and the negative pressure reading

Keyword:

Floating roof oil tank

General contracting of petrochemical construction

General contracting of construction engineering

General contracting of electromechanical engineering construction

General contracting of penstock construction

Inquiry

Contact

Headquarter address: Floor 8, Shui'an International Office Building, Sanjiao Road, Heping Avenue, Wuchang District, Wuhan, Hubei Province

Factory address: Shuangliu Gulong Economic Development Zone, Yangluo District, Wuhan

Follow us

Quick navigation